Energy conversion - REMIND-MAgPIE

| Corresponding documentation | |

|---|---|

| Previous versions | |

| Model information | |

| Model link | |

| Institution | Potsdam Institut für Klimafolgenforschung (PIK), Germany, https://www.pik-potsdam.de. |

| Solution concept | General equilibrium (closed economy)MAgPIE: partial equilibrium model of the agricultural sector; |

| Solution method | OptimizationMAgPIE: cost minimization; |

| Anticipation | |

The core part of the energy system is the conversion of primary energy into secondary energy carriers via specific energy conversion technologies. Around fifty different energy conversion technologies are represented in REMIND. In general, technologies providing a certain secondary energy type compete linearly against each other, i.e. technology choice follows cost optimization based on investment costs, fixed and variable operation and maintenance costs, fuel costs, emission costs, efficiencies, lifetimes, and learning rates. REMIND assumes full substitutability between different technologies producing one energy type. The various secondary energy carriers included in REMIND are:

- Electricity

- Gases

- Liquids

- Hydrogen

- Solid fuels

- District heat and local renewable heat

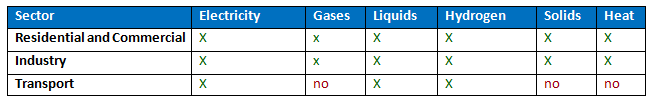

<xr id="tab:REMINDtable_3"/> gives an overview over which energy carriers are used in which end use sector.

Table 1. Overview of energy carriers used in end-use sectors

<figtable id="tab:REMINDtable_3">

REMIND specifies each technology through a number of characteristic parameters

- Specific overnight investment costs that are constant for most technologies and decrease due to learning-by-doing for some relatively new technologies (see below).

- Cost markups due to financing costs over the construction time.

- Fixed yearly operating and maintenance costs in percent of investment costs.

- Variable operating costs (per unit of output, excluding fuel costs).

- Conversion efficiency from input to output.

- Capacity factor (maximum utilization time per year). This parameter also reflects maintenance periods and other technological limitations that prevent the continuous operation of the technology.

- Technical lifetime of the conversion technology in years.

- If the technology experiences learning-by-doing: initial learn rate, initial cumulative capacity, as well as floor costs that can only be approached asymptotically.

REMIND represents all technologies as capacity stocks with full vintage tracking. Since there are no hard constraints on the rate of change in investments, the possibility of investing in different capital stocks provides high flexibility for technological evolution. However, the model includes cost mark-ups for the fast up-scaling of investments into individual technologies; therefore, a more realistic phasing in and out of technologies is achieved. The model allows for pre-mature retirement of capacities before the end of their technological life-time (at a maximum rate of 4 %/year), and the lifetimes of capacities differ between various types of technologies. Furthermore, depreciation rates are relatively low in the first half of the lifetime and increase thereafter.

Each region is initialized with a vintage capital stock and conversion efficiencies are calibrated to reflect the input-output relations provided by IEA energy statistics (IEA 2007a; IEA 2007b). The conversion efficiencies for new vintages converge across the regions from the 2005 values to a global constant value in 2050. Furthermore, for some fossil power plants, transformation efficiencies improve exogenously over time. Finally, REMIND adjusts by-production coefficients of combined power-heat technologies (CHP) by region to meet the empirical conditions of the base year.

Only two technologies convert secondary energy into secondary energy, namely the production of hydrogen from electricity via electrolysis and the opposite route, the production of electricity from a hydrogen turbine.

Technology choice for energy supply follows cost optimization based on investment costs, fixed and variable operation and maintenance costs, fuel costs, emission costs, efficiencies, lifetimes, and learning rates. Endogenous technological change (learning-by-doing) influences wind and solar investment costs. For fossil fuel power plants, some exogenous time-dependent improvement of efficiency parameters until 2050 and convergence of efficiencies that are regionally calibrated to observed 2005 values are implemented. REMIND assumes full substitutability between different technologies producing one final energy type.